Quality control

Quality is a reflection of the work we present to YOU.

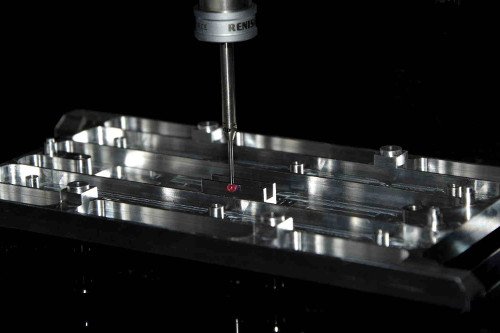

The quality of our drawing parts is our top priority. That is why we check every batch. We attach great importance to compliance with all tolerances and pay special attention to functionally relevant dimensions. Quality is no coincidence for us.

The company's mission statement and processes are geared towards quality. Each drawing part is subject to constant quality controls, guaranteed by a fully equipped QA department.

The specification of part-specific inspection lot sizes is also no problem for us.

The complexity of dimensions and fits varies greatly for customised products. It may therefore make sense to increase or decrease the inspection lot size in order to optimise costs and quality. We are also happy to accept your specifications for inspection lot sizes if required.

Our parts can be tested in-house in a wide variety of ways. Our repertoire of measuring devices totals around 1000.

OUR EQUIPMENT

- CNC measuring machine (tactile and optical)

- Hand-guided measuring machine

- Hardness tester

- Profile projector

- Various internal micrometers

- Various dial gauges with various measuring probes

- Roughness depth gauge

- Various micrometers

- Various calipers

- Various test mandrels and rings

- Various gauges

- etc.

In addition to our own commitment to quality, we regularly undergo certification.

In addition to the established and validated DIN ISO 9001 quality management system, we are also committed to the environment and are certified to DIN/EN 14001.

How to reach us:

Tel.: +49 (0) 7940/9200-0

Fax: +49 (0) 7940/9200-50

E-Mail: info@pv-gmbh.com

Or you can simply use our online enquiry form